From industrial automation HMI panel PC to other HMI solutions, here’s what they are, how they work, what benefits they bring, and everything you should know about industrial automation HMI.

What do we mean when we hear about HMI solutions and industrial automation HMI? The acronym denotes the term “Human-Machine Interface” and refers to a technology that enables simple and immediate communication with machines and systems in an industrial plant. This type of technology can take many forms, from a tablet to a dashboard embedded in machinery, with either a central facility or several interconnected devices. Thanks to the circulation of an ever-growing number of connected devices, HMI automations are able to integrate with IoT technology networks, collecting increasingly voluminous and complex data. The spread of HMI solutions is increasing in parallel with the spread of IoT. The goal of industrial automation HMI is to support industries in the face of ever-increasing complexity of plant and infrastructure management, enabling access to operational data and direct control over machinery actions.

Using HMI interface solutions and industrial automation HMI

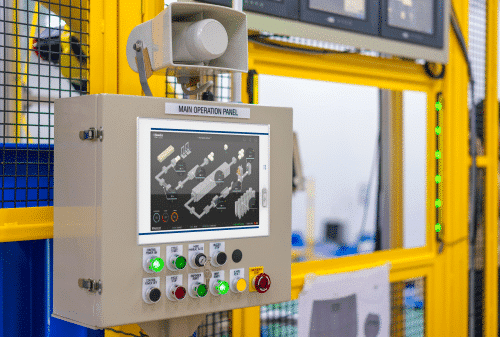

Solutions such as displays and touch screens for industrial automation HMI panel PC are created to allow a high level of customization for targeted configuration according to the specific needs of each sector. First and foremost, the manufacturing sector is certainly the one that most exploits the use of HMI automations, from textiles to paper, via pharmaceuticals, electronics, food and much more. HMI solutions are extremely flexible and adapt to the complexity of the system on which they are installed and to the purpose for which they are intended, whether it is plant control, parameter variation, productivity increase or more. For this reason, HMI automations are an important resource in the control of buildings, plants, and vehicles to support many professionals, including engineers, machine operators, and systems integrators. HMI solutions are usually used in industrial environments for graphical user interface screens so that data and information can be displayed through graphs, tables, images, and other visual elements to facilitate interpretation. Corrective action is also facilitated by being able to handle alerts and emergencies quickly and in a timely manner directly from the screen.

Why adopt industrial automation HMI panel PC and other HMI solutions?

Industrial automation HMI aims to help operators manage the complexity of industrial control systems, which are increasingly complex and constantly evolving, thanks to clear and extremely flexible interfaces. Agile communication with machinery allows at a general level the optimization of the production cycle, but let’s look specifically at some of the main advantages of HMI solutions:

- Ease of use by reporting data through easy and intuitive tools such as graphs, tables, images, often with indicators that emphasize the most significant and urgent information;

- Customization, that is, the ability to set up and modify HMI solutions according to your needs;

- Increased efficiency by constantly monitoring information so that changes and corrections can be made in real time, thereby also managing to reduce downtime and waste;

- Prevention-Reporting and data analysis of HMI industrial automation systems enable the detection of machinery and plant anomalies so that errors or malfunctions that could slow down production can be prevented;

- Remote control, to control operations from the office, from home, while traveling, or from anywhere and anytime;

- Overview: HMI automations make it possible to control all machine performance from a single device, so you can always have an overview of the entire production cycle, monitor its progress and promptly correct any errors. In addition, all users can access information in real time and constantly update the entire department.

Within an increasingly competitive and articulated market, with the decisive role that data collection and analysis for industrial processes have assumed, the future of industrial automation passes through HMI solutions. For this reason, HMI interface automations for industrial vehicles are also set to introduce and integrate with Artificial Intelligence and Virtual Reality in pursuit of ever higher performance.